Automated Glass Cutting and Breaking Line

Automated Glass Cutting and Breaking Line: Precision CNC and High-Speed Production

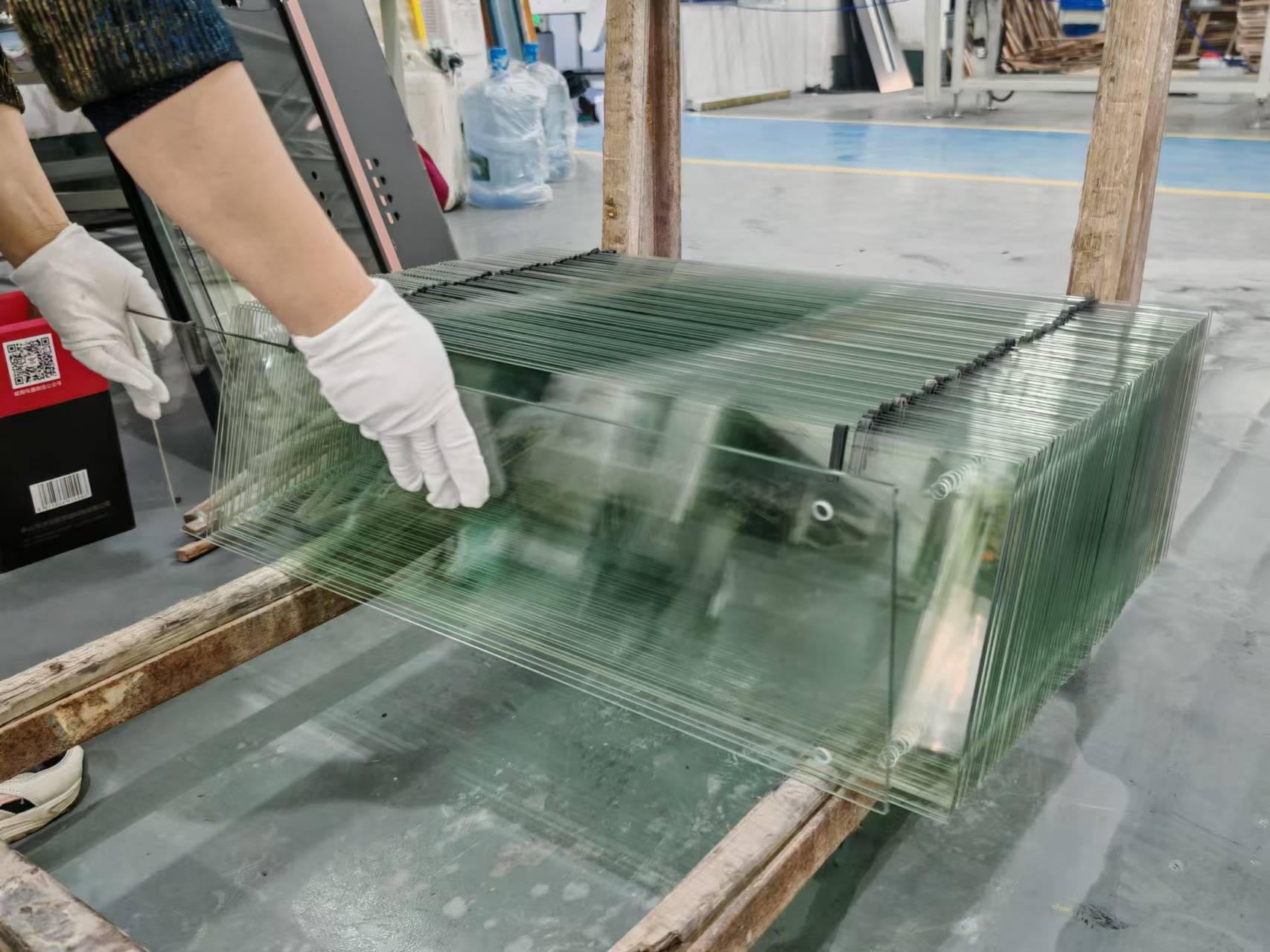

In the rapidly evolving world of glass processing, automation and precision are crucial for efficiency. Our state-of-the-art production line is designed to handle glass sheets of 1830*1220mm, producing smaller glass pieces down to 454*404mm, with thicknesses ranging from 1.5mm to 10mm. This fully automated system ensures high-speed operations, allowing for unattended production while seamlessly feeding into your own cleaning equipment. This setup achieves fast production cycles of ≤12 seconds per piece, ensuring a steady flow of processed glass for further production needs.

Production Line Components:

- SY-1813-U Automatic Suction Glass Loader

- SY-1813-C CNC Glass Cutting Machine

- X-Break-Out Automatic Horizontal Breaking Machine

- Y-Break-Out Automatic Vertical Breaking Machine

Equipment Overview:

1. SY-1813-U Automatic Suction Glass Loader

This unit is responsible for automatically loading glass sheets into the cutting process. It features a double-sided suction system with vacuum control for secure handling of glass sheets.

-

Mechanical Configuration:

- Flip Chain: Custom high-precision reinforced chain

- Transmission Rollers: Imported PU material

- Vacuum Suction Cups: Imported nitrile rubber (double adsorption)

- Transmission Motor: Domestic reduction motor with variable frequency drive

-

Electrical Components:

- PLC Controller: Delta Taiwan

- Touch Screen: Delta Taiwan

- Proximity Switches: Sone

- Main Electrical Components: Chint

- Pneumatic Parts: Airtac Taiwan

- Vacuum Pump: Domestic specialized vacuum pump

Technical Specifications for SY-1813-U Loader:

| Parameter | Details |

|---|---|

| Min. Glass Size | 1500*1200mm |

| Max. Glass Size | 1830*1220mm |

| Glass Thickness Range | 1.5-10mm |

| Cycle Time | 40-60s (adjustable) |

| Max Suction Depth | 600mm |

| Loading Capacity | 300KG |

| Power Supply | 380V/50Hz |

| Installed Power | 8KW |

| Compressed Air | 0.3Mpa – 0.5Mpa |

| Vacuum Pressure | -70 to -90Kpa (adjustable based on thickness) |

2. SY-1813 CNC Glass Cutting Machine

This CNC cutting machine is built for precise cutting with full automation, featuring an X-Y-Z three-axis motion system for perfect control.

- Structure: Horizontal setup with rack and pinion and linear guides

- Drive: Servo motor-driven

- Cutting Range: Up to 1830*1220mm, minimum 200*200mm

- Cutting Thickness: 1.5-10mm (requires adjustment for different thicknesses)

Technical Specifications for SY-1813 Cutting Machine:

| Parameter | Details |

|---|---|

| Max Glass Size | 1830*1220mm |

| Min Glass Size | 200*200mm |

| Glass Thickness | 1.5-10mm |

| Accuracy (Line Parallelism) | ≤±0.2mm/m |

| Diagonal Accuracy | ≤±0.45mm/m |

| Cutting Speed | 0-120m/min (adjustable) |

| Power Supply | 380V/50Hz |

| Installed Power | 8KW |

3. X-Break-Out Horizontal Breaking Machine

This machine ensures the precision breaking of glass along the horizontal axis, using pneumatic control for top and bottom supports.

Technical Specifications for X-Break-Out Machine:

| Parameter | Details |

|---|---|

| Max Glass Size | 1830*1220mm |

| Post-Breaking Size | 456*404mm (customizable) |

| Power Supply | 3KW |

4. Y-Break-Out Vertical Breaking Machine

Similar to the horizontal breaker, this machine handles vertical glass breaking with precise control, ensuring accuracy in every break.

Technical Specifications for Y-Break-Out Machine:

| Parameter | Details |

|---|---|

| Max Glass Size | 500*1220mm |

| Post-Breaking Size | 456*404mm (customizable) |

| Power Supply | 3KW |

Why Choose Our Fully Automated Line:

- High Precision: Achieves ±0.2mm accuracy, ensuring optimal cutting and breaking results.

- Customizable: Easily adjustable for different glass sizes and thicknesses, including the use of imported components for quality.

- Full Automation: Supports 24/7 unattended operation, drastically reducing labor costs while maximizing production.

- Fast Production: Designed to meet the fastest production cycles of ≤12 seconds per piece, ideal for high-demand operations.

- Integrated Design: Includes automatic feeding, cutting, and breaking in a single, streamlined process.

- Durable Components: Uses top-quality imported and domestic parts, ensuring longevity and performance.

- High Precision and Efficiency

- Environmental and Cost Efficiency

- Innovative Technology

- Customization and Upgrades

- Global Service

Client Details

Better finance and consulting 654, NewYork-22

Service Provided

Financing, Marketing, Tax Advising, Consulting

Project Timeline

5 Days planning, and 1 month for completion

Stay Updated with Our Blog!

Discover the latest in laser cutting services and glass cutting technologies at Hintan-Tech. From expert insights on glass laser cutting to finding laser cutting near you, our blog covers everything you need to know about precision glass cut solutions and advancements in the industry.