Quartz Ceramic Rollers Specifically for Glass Tempering Furnaces

Quartz Ceramic Rollers Specifically for Glass Tempering Furnaces

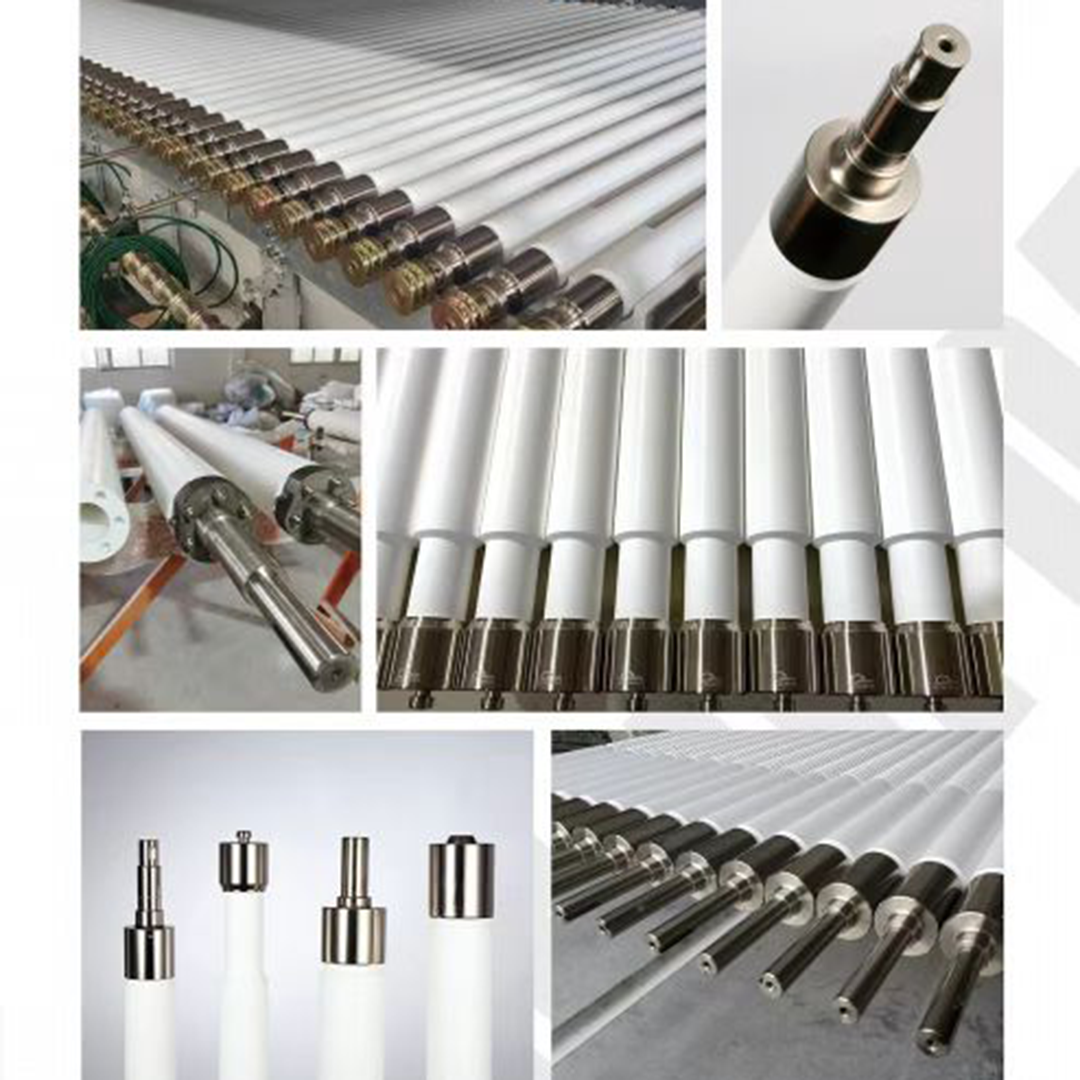

Quartz Ceramic Rollers are essential components serving as horizontal conveying rollers in critical industrial processes. Their primary applications include flat and curved glass tempering furnaces, curing furnaces, sintering furnaces, and hot stamping forming lines in photovoltaic glass production.

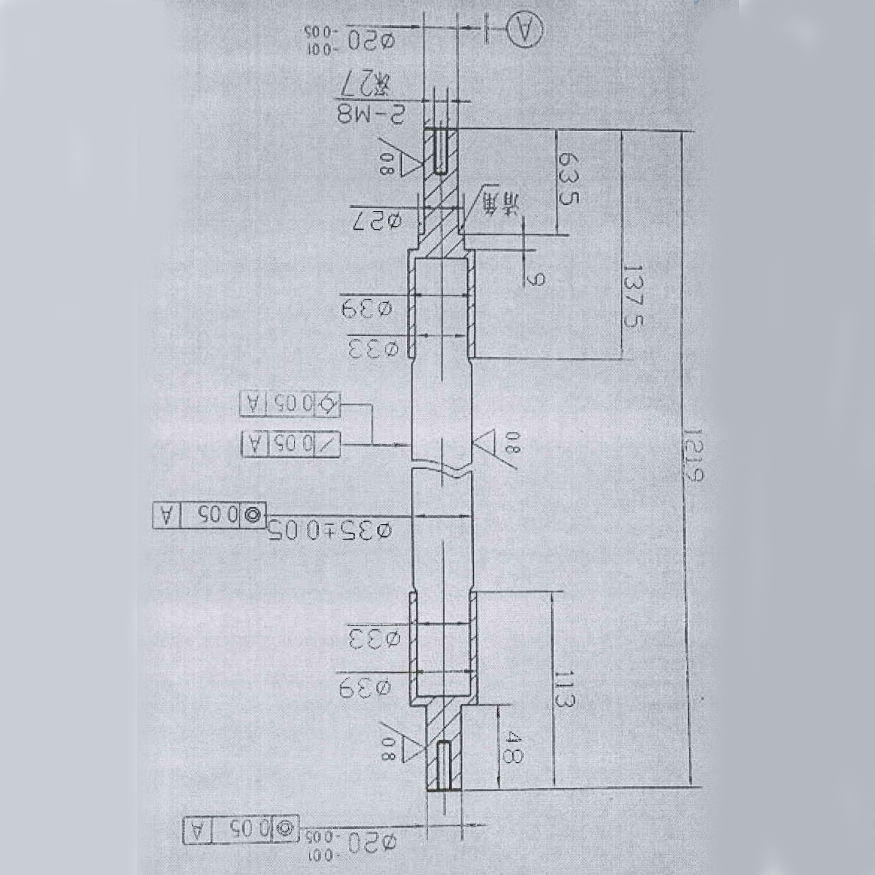

These fused quartz ceramic rollers are favored for their exceptional physical properties, which directly translate to superior performance and long service life. Key advantages include high density and high strength, ensuring minimal deformation under extreme heat for outstanding high-temperature stability. Furthermore, their excellent surface smoothness (Ra 0.6-1.0) and extremely low radial runout (<0.10mm) guarantee precise, consistent product handling.

Manufactured by Xinyi Zhengda High-tech Quartz Materials Co., Ltd., a National High-tech Enterprise, our CEPICS series rollers are produced under stringent ISO9001 certified quality control. From raw material selection to the final product featuring our unique shaft-end connection and protection technology, every step is monitored to deliver pore-free, reliable ceramic rollers that meet or exceed industry standards for float glass furnaces and silicon steel annealing furnace applications.

Product Advantages

-

Special shaft-end protection treatment ensures the shaft end does not loosen or detach.

-

Excellent physical properties with stable performance under normal working conditions.

-

Full-process monitoring from raw materials to finished products.

-

Excellent surface smoothness.

-

Comprehensive range of design specifications.

-

Complete service support.

-

Unique shaft-end connection technology.

Product Series

-

Quartz Ceramic Rollers for Flat/Curved Glass Tempering Furnaces

-

Quartz Ceramic Products for Float Glass Furnaces

-

Quartz Ceramic Products for Silicon Steel Annealing Furnaces

-

Special Ceramic Rollers for Photovoltaic Glass Production Lines

Product Characteristics

Physical Characteristics of Fused Quartz Ceramic Roll

| Name | Unit | Values |

|---|---|---|

| SiO₂ Content | % | ≥99.6 |

| Density | g/cm³ | ≥1.95 |

| Bending Strength (20°C) | MPa | 30~40 |

| Bending Strength (700°C) | MPa | 45~60 |

| Elastic Modulus | GPa | 30~40 |

| Coefficient of Thermal Expansion | 10⁻⁶/K | 0.5~0.9 |

| Water Absorption Rate | % | 4.5~6.0 |

| Apparent Porosity | % | 7~11 |

| Mean Pore | μm | ≤0.4 |

| Material Properties | High density, high strength, pore-free | |

| Usage Effect | Long service life, good stability (does not sag easily) |

Appearance Quality of Fused Quartz Ceramic Roller

| Name | Unit | Values |

|---|---|---|

| Surface Roughness | Ra | 0.6-1.0 |

| Radial Runout of Ceramic Roller | mm | <0.10 |

Other physical and chemical indicators for the fused quartz ceramic rollers comply with the JC/T687-2010 standard, however, the internal standards implemented by our company are superior to this standard.

Client Details

Better finance and consulting 654, NewYork-22

Service Provided

Financing, Marketing, Tax Advising, Consulting

Project Timeline

5 Days planning, and 1 month for completion

Stay Updated with Our Blog!

Discover the latest in laser cutting services and glass cutting technologies at Hintan-Tech. From expert insights on glass laser cutting to finding laser cutting near you, our blog covers everything you need to know about precision glass cut solutions and advancements in the industry.