Industrial Glass Laser Marking Machine

Industrial Glass Laser Marking Machine - Hintan-Tech

High-Speed Glass Laser Coding System

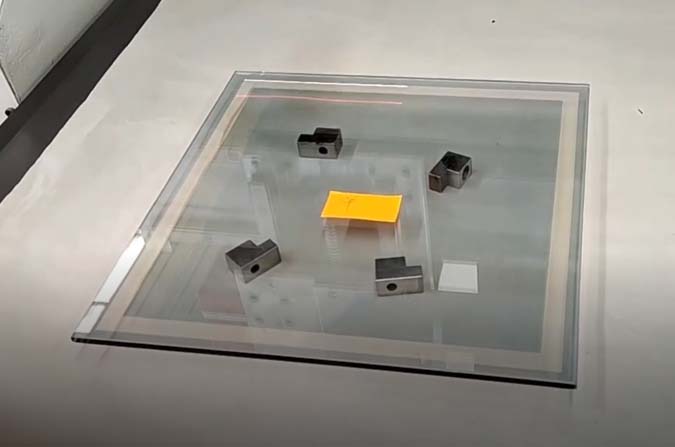

To address the challenges of permanence, high precision, and high-speed production in industrial glass identification, Hintan-Tech introduces the CNC Fiber Laser Marking System. Operating stably in a cleanroom environment, it is more than just a machine; it is an automated laser coding and engraving center specifically designed to upgrade your existing glass production line.

Surpassing traditional inkjet or chemical etching, this fiber laser system provides a one-stop solution for Automotive Glass VIN Code Marking, Medical Glass Vial Serial Number Coding, Solar Panel Glass Identification, and precision engraving for furniture and decorative glass. Whether meeting the cycle time demands of high-volume glass processing or achieving permanent deep marks on architectural curtain wall glass, this industrial-grade laser marking machine delivers exceptional performance.

Core Value Proposition

Our Glass Laser Marking Machine is a complete Industrial Marking Solution. Its core value lies in:

Built for Production Lines: Designed for seamless integration into automated glass production lines, featuring robotic loading/unloading interfaces for effortless connection with cutting, edging, and washing processes. It is a true High-Speed Glass Laser Coding System.

Solves Industry-Specific Challenges: With adjustable pulse width (as low as 10ns) and precise temperature control, it achieves Crack-Free Laser Marking on Tempered Glass, meeting the stringent requirements of architectural glass and appliance panel manufacturers.

Covers Full Industry Applications: From micro-scale text marking on electronic glass covers to intricate pattern engraving for Glass for Furniture and Home Decor (e.g., tabletops, cabinet doors), a single machine handles diverse, high-value Glass Engraving for Furniture and Home Decor needs.

Comprehensive Process Upgrade: Directly replaces inefficient, polluting inkjet marking or manual screen printing, helping clients complete the transition from Inkjet to Laser Marking on Glass, enhancing product quality and production efficiency.

- Maximum Processing Size.

- Laser Type.

- Decoating Efficiency.

- Machine Dimensions.

Detailed Smart Operation Process

Step 1: Integrate the Robotic Arm

Install and connect the robotic arm for automatic workpiece handling. This step is key to embedding the system into a fully automated glass processing line, ensuring continuity and reliability for High-Volume Glass Processing.

-

Core Value: Reduces manual intervention, eliminates handling errors, and provides the foundation for 24/7 operation for automotive glass manufacturers or glass bottle plants.

Step 2: Intelligent Software Control

Operate via the dedicated MOKE laser marking software. It supports “Fast Mode” for rapid batch marking and “Step Mode” for fine alignment and micro-engraving of high-precision glass (e.g., microscope slides).

-

Core Value: CNC-level control ensures every mark on a medical glass vial or solar glass panel is perfectly consistent and clearly readable.

Step 3: Set the Precision Work Origin

Define the workpiece coordinate system origin and enable synchronous and zone modes. This procedure is crucial for marking on curved glass (e.g., automotive mirrors) and ensuring absolute positional accuracy for hundreds of marks on a full sheet of glass panel.

Step 4: Import Graphics and Start Marking

Import vector files (.plt, .dxf). Optimize parameters for different materials and effects, for example:

-

For High-Speed Line Coding: Use radial scanning at speeds up to 8000 mm/s, 30% power for fast coding of glass bottles or electronic components.

-

For Deep Engraving Effects on Decorative Glass: Adjust layer thickness and ring count to create artistic patterns with a three-dimensional feel.

Steps 5-7: Achieving Multiple Advanced Effects

-

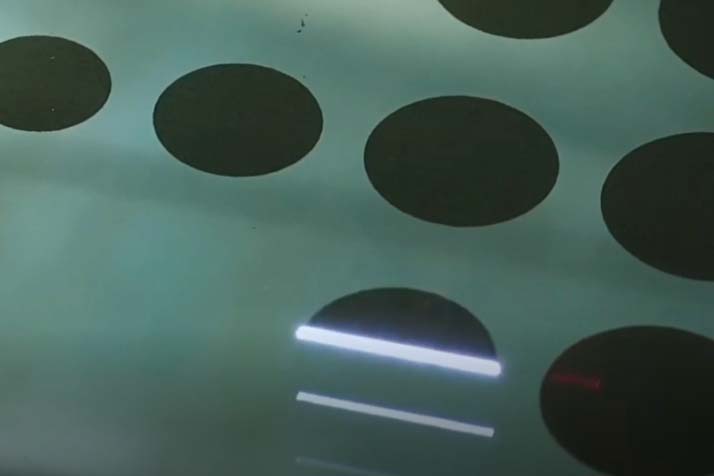

Frosted/Sandblasted Effect: Parameters (30% power, 5000 mm/s speed) create a uniform matte texture directly on the glass surface, perfect for decorative glass without the complexity of traditional sandblasting booths.

-

High-Transparency Mirror Effect: A specific frequency (150kHz) and pulse width (10ns) combination enables damage-free, highly transparent marking inside the glass, ideal for premium display case glass or instrument panels.

-

Precision Drilling & Multi-Layer Marking: Using high power (96%) and multiple ring settings enables micro-hole drilling in glass or creating complex, layered anti-counterfeiting marks, meeting the sophisticated processing needs of industrial glass components.

Industrial Glass Laser Marking Machine Technical Parameters Table

| Parameter | Typical Value / Range | Associated Industrial Application & Benefit |

|---|---|---|

| Laser Type | Fiber Laser | Excellent beam quality for fine, permanent marking on electronic glass and automotive glass. Low maintenance. |

| Marking Speed | 5000 – 8000 mm/s | Meets the high cycle time requirements of high-volume glass processing equipment, enabling high-speed online flying marking. |

| Laser Power | 30% – 96% (Adjustable) | 30% for high-transparency surface marking, 96% for deep engraving or glass drilling. A versatile single machine. |

| Repeatability | ±0.02 mm | Ensures absolute precision for every serial number on a medical glass vial and every QR code on automotive glass. |

| Working Area | Customizable | Adapts to processing needs from small glass covers to large architectural curtain wall glass. |

| Integration Interface | Robot, PLC | Easily upgrade your existing glass production line to achieve a closed-loop smart factory. |

Why Choose Hintan-Tech's Industrial Laser Marking Solution?

-

✅ Industry Focus: Designed specifically for automotive glass, photovoltaic glass, furniture/decorative glass, and electronic glass industries with targeted process solutions.

✅ Production Line Mindset: Not just a standalone machine, but a Turnkey Laser Marking Workstation seamlessly integrable into your existing glass production line.

✅ Process Innovation: Solves industry pain points like cracking on tempered glass and low contrast on black glass, achieving effects impossible with traditional methods.

✅ Long-Term Investment: As a low-maintenance industrial laser marker, its high reliability and long lifespan significantly reduce your total cost of ownership.

Ready to Revolutionize Your Glass Marking Process with Laser Technology?

If you are seeking answers to “how to achieve permanent marking on solar glass frames” or “how to upgrade our inkjet line to pollution-free laser marking,” Hintan-Tech’s industrial laser experts are ready to support you from evaluation to full integration.

Contact us today for a laser marking solution tailored to your industry and an on-site process test.

Client Details

Better finance and consulting 654, NewYork-22

Service Provided

Financing, Marketing, Tax Advising, Consulting

Project Timeline

5 Days planning, and 1 month for completion

Stay Updated with Our Blog!

Discover the latest in laser cutting services and glass cutting technologies at Hintan-Tech. From expert insights on glass laser cutting to finding laser cutting near you, our blog covers everything you need to know about precision glass cut solutions and advancements in the industry.