Automatic Glass Cutting and Breaking Machine

Automatic Glass Cutting & Breaking Machine for 1220*913 Glass – High Precision & Efficiency

When it comes to advanced glass processing, this machine is engineered to handle cutting and breaking operations for 1220*913 glass along the 913mm width side with precision and automation. It divides the task into five essential parts:

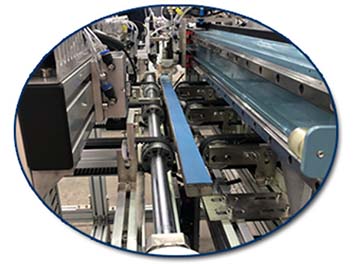

- Positioning conveyor mechanism for accurate glass alignment,

- Gantry-style cross-cutting mechanism combined with a glass chip cleaning and adsorption system for debris-free cutting,

- Length-setting mechanism that ensures precision in every cut,

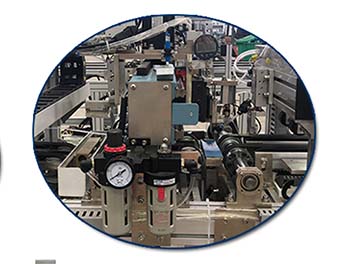

- Cutting line heating system to enhance cutting efficiency,

- Liftable breaking mechanism and a discharging system to seamlessly move the finished glass.

This machine provides a high level of automation, reducing labor and maximizing production efficiency.

Processing Parameters:

| Parameter | Details |

|---|---|

| Processing Speed | Handles small glass pieces at 10 seconds per piece |

| Processing Range | 1220*913mm, Thickness: 1.1—3mm (customizable) |

| Accuracy | ±0.3mm |

| Cutting Pressure | Adjustable from 0.3—0.9Mpa |

Configuration:

- Rack and Guide Rails: Imported for enhanced durability and precision

- Motor: Delta servo motor for consistent power

- Timing Belt: Imported from Fukuda for superior reliability

- Synchronous Pulley: Domestic, crafted from aluminum alloy

- Beam: Welded square tube or aluminum profile for strength and stability

- PLC and Touch Screen: Mitsubishi (excludes the small glass washer)

- Base Frame: Square tube or aluminum profile

- Electrical Components: Great Wall or Chint for stable performance

- Loading and Unloading: Proprietary positioning system (custom-made)

- Optical Sensor Switch: Sone brand for precision sensing

- Cutting Wheel: High-quality German import for long-lasting sharpness

- Proportional Valve: SMC from Japan for precise pressure control

- Heating Device: Domestic, providing efficient heat application

- Vacuum Suction System: Domestic, ensuring strong and reliable glass handling

Why It Stands Out:

This machine’s combination of high-precision cutting, robust configuration, and unmatched automation makes it ideal for high-efficiency glass production lines. From customizable configurations to imported components, it delivers unattended operation, minimizing downtime and ensuring every piece meets exact specifications. It’s not just a machine—it’s a leap forward in glass processing technology.

- High Precision and Efficiency

- Customization and Upgrades

Client Details

Better finance and consulting 654, NewYork-22

Service Provided

Financing, Marketing, Tax Advising, Consulting

Project Timeline

5 Days planning, and 1 month for completion

Stay Updated with Our Blog!

Discover the latest in laser cutting services and glass cutting technologies at Hintan-Tech. From expert insights on glass laser cutting to finding laser cutting near you, our blog covers everything you need to know about precision glass cut solutions and advancements in the industry.