Waterjet Cutting Glass Machine Systems

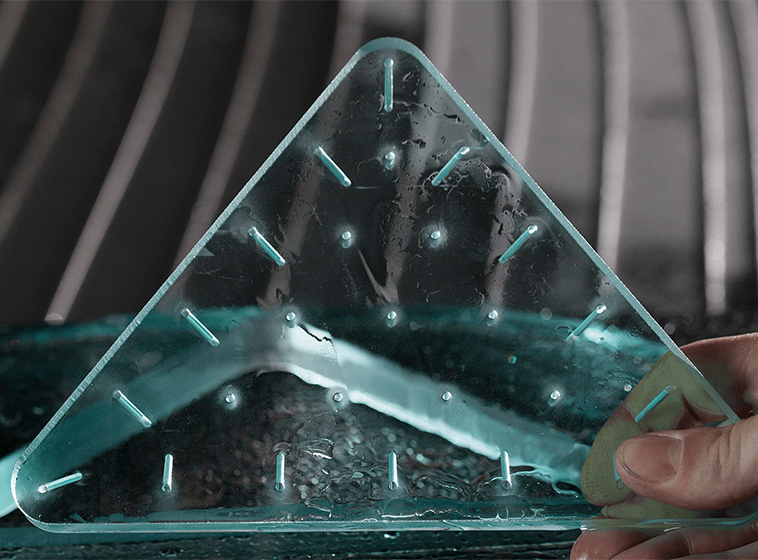

Cutting Glass with Waterjet

Introduction

Hintan-Tech Waterjet Cutting Machines revolutionize glass fabrication with advanced technology solutions that combine speed, precision, and versatility. Whether you’re crafting intricate stained glass, automotive windshields, or architectural facades, our waterjet cutting systems deliver flawless results for industries ranging from aerospace to interior design.

Key Advantages of Waterjet Cutting

✅ Unmatched Precision & Versatility:

Zero Heat-Affected Zones (HAZ): Eliminate thermal stress and cracks, even when cutting thick glass (up to 150mm).

Omni-Directional Cutting: Achieve complex curves, tight corners, and intricate patterns without tool changes.

Minimal Kerf (0.8–1.2mm): Reduce material waste and enable near-net cutting with minimal finishing.

✅ Cost-Effective Production:

Automated Design Integration: Robotic cells and CNC machine solutions boost productivity for high-volume orders.

Low Operating Costs: Durable components like KMT Waterjet pumps and efficient metering systems minimize maintenance.

✅ Eco-Friendly & Safe:

No Hazardous Fumes: Ideal for decorative art and electronics where clean edges matter.

Garnet Abrasive Recycling: Optional systems reduce waste and keep workspaces clean.

Applications Across Industries

| Industry | Use Cases |

|---|---|

| Architectural | Facade panels, windows, partitions, sintered stone |

| Automotive | Windshields, sunroofs, side windows with precision-cut curves |

| Aerospace | Aircraft windows, interior components requiring flawless edges |

| Art & Design | Stained glass mosaics, sculptures, custom water jet decorative art |

| Electronics | Touchscreen substrates, smartphone glass with micro-detailed cuts |

| Furniture | Glass countertops, shelves, and tabletops with polished edges |

Technical Specifications

Machine Types: Gantry-style systems with servo ballscrew-driven X/Y/Z axes.

Standard Size: 4’ x 8’ (customizable for slitter machine integration).

Pressure Options: 60–90 kpsi KMT pumps for cutting water-based applications.

Abrasive System: Automatic garnet suspension/removal for noise reduction and cleanliness.

Multi-Nozzle Option: Dual nozzles with manual/automatic offset control.

Why Choose Hintan-Tech Waterjet Machines?

Advanced Automation:

Automatic parts handling and robotic cells streamline production.

UltraPierce™ Technology: Pierce delicate glass without cracking.

Global Support:

Localized service networks for waterjet cutting near me needs.

OEM-certified manufacturing machines with 24/7 technical support.

Scalable Solutions:

From compact systems for artists to industrial slitter machine-ready setups.

Client Details

Better finance and consulting 654, NewYork-22

Service Provided

Financing, Marketing, Tax Advising, Consulting

Project Timeline

5 Days planning, and 1 month for completion

Stay Updated with Our Blog!

Discover the latest in laser cutting services and glass cutting technologies at Hintan-Tech. From expert insights on glass laser cutting to finding laser cutting near you, our blog covers everything you need to know about precision glass cut solutions and advancements in the industry.